PCBGOGO, a professional PCB prototype and assembly manufacturer | We make you satisfied

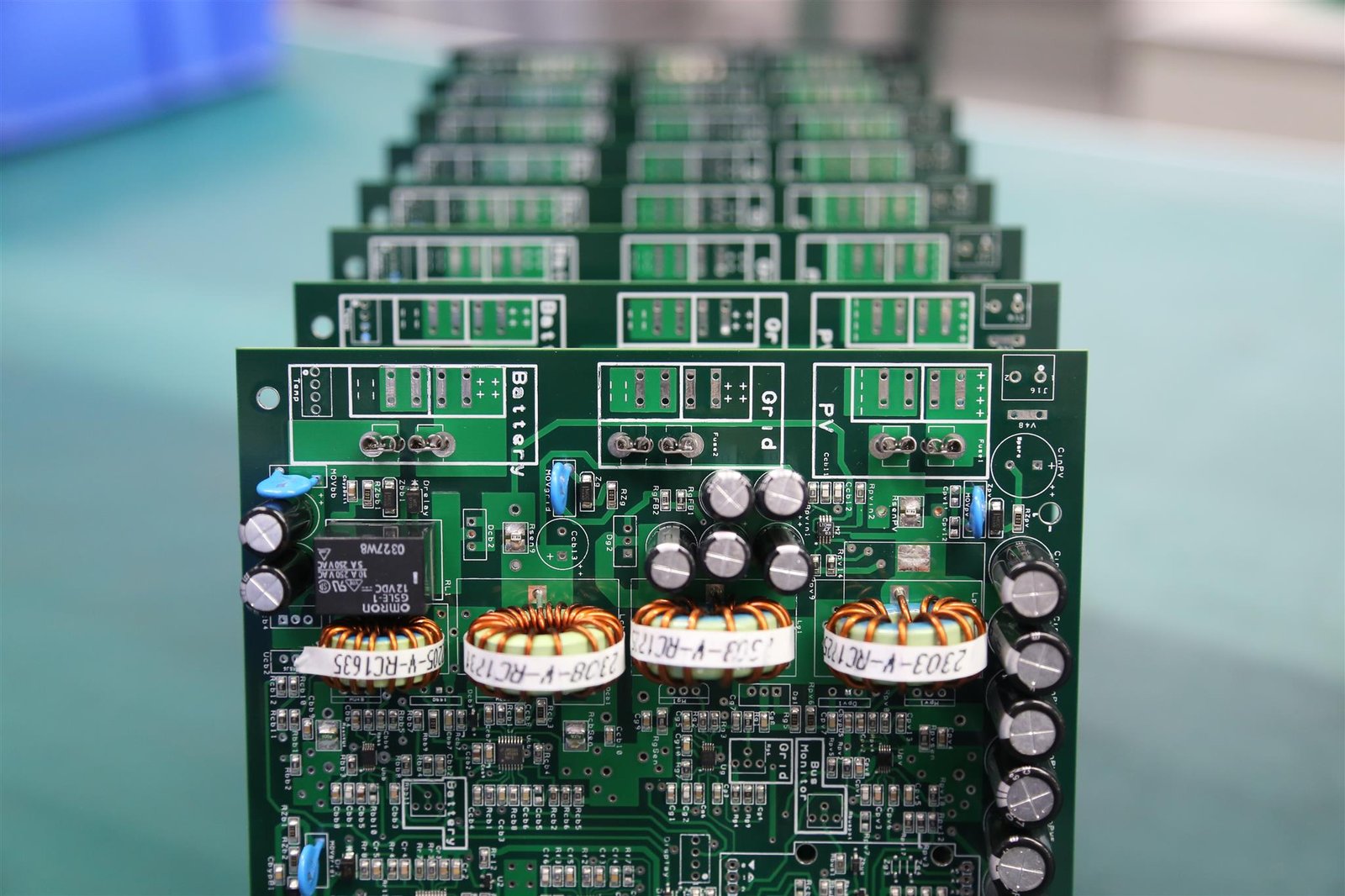

With the development of business, PCBGOGO has a great boom in recent years making us one of the largest and most popular PCB manufacturers in China.

As we all know, PCBGOGO has over 20 years’ experience in PCB prototype and assembly manufacturing services, highly specialized not only in quick-turn PCB prototype and PCB assembly, but also medium and small volume fabrication.

And it’s amazing that PCBGOGO has invested 20 million dollars in enlarging the factory and purchasing the machine to meet the customers’ demands this year, “customer always is first”, and PCBGOGO is trying its best to achieve the overall business goal.

On one hand, the factory is broadening five times from 3000 square to 15000 square in September 2018, which would cover SMT, PCB prototype and assembly line, PCB layout team, the engineer’ s office and so on. At the same time, DES line and VCP copper plated machine is brought in PCBGOGO, it can’t be denied that DES is doing well in automatic voltage regulation and working speed when PCBGOGO makes PCB prototype, such as the homogeneity of etching is over 96%, working speed is 4 metre per minute, and the capacity of board testing is 0.036~3.2mm, and monthly shipment is up to 100000 pieces with the working of DES and VCP, improving PCB fabrication and optimizing PCB prototype.

One the other hand, there are seven new drilling machines in PCB fabrication, and two drilling machines are working now, one is with 6 heads, another is 4 heads, compared with normal PCB digital control drilling machine, the drilling machine with 6 heads is making full use of the advanced digital control drilling machine at home and abroad equipping with the device of automatic tool change and tool break testing with closed loop control, also, the key components of 6 heads is the most powerful from aboard, which makes a great progress in drilling speed, precision and stability when PCBGOGO makes PCB prototype.

And the drilling machine with 4 heads is the second drilling and milling volume since making PCB prototype, drilling precision is within ±0.005mm, feeding and fabrication are working together, and makes a great contribution to PCBGOGO in PCB fabrication.

In addition, PCBGOGO has brought in silkscreen printer, which is mainly in exposing and developing for circuit board, and it operates easily with UV curing system just 2seconds and allows different PCB silkscreen printing, compared with the traditional screen printing, silkscreen printer improves PCB fabrication’s efficiency and makes PCB prototype with environmental protection printer,and simplify PCB manufacturing process, shorten PCBGOGO manufacturing cycle, what’s more, silkscreen printer achieves the goal of energy saving and emission reduction.

Now PCBGOGO has brought in the panel machine, it’s PCBGOGO latest panel design and automatic control with PLC, which is not only realizing automatic coating、feeding and connecting material but also full-automatic panel, it’s saving PCB fabrication’s cost with panel machine, and reducing PCBGOGO’s manual operation and improving PCB fabrication’s efficiency, optimizing PCB prototype and increasing PCB fabrication scale and so on.“Quality and Efficiency doesn’t Stop here”, our COO Eric Wu says, PCBGOGO is now making PCB prototype and assembly for all your needs and tries our best to keep customers satisfied.

There is no doubt that PCBGOGO now is a professional and trustworthy PCB prototype manufacturer with high quality, and quick-turn PCB assembly turnkey services. PCBGOGO is looking forward to cooperate with you.

[adrotate group=”1″]

[adrotate group=”2″]