Blog

Recent Posts

Arduino Projects

Basic Introduction to NextDFM software

10 Tips to choose a Prototype PCB Assembly Manufacturer

CONTACTLESS AUTOMATIC WARDROBE LED LIGHT WITH FADE EFFECT

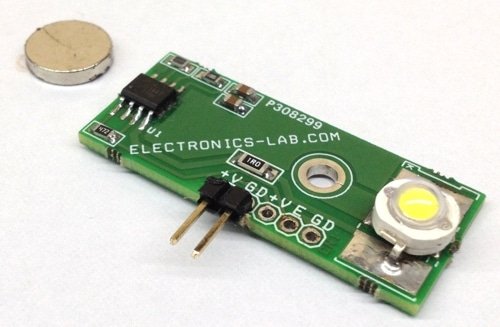

LUX METER MODULE

SOUND ACTIVATED SWITCH – RELAY

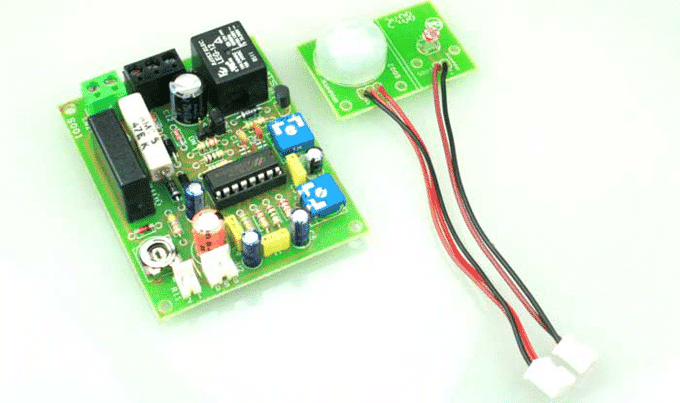

PIR SENSOR

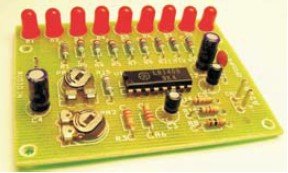

AUDIO VU METER 9 LEDS

IR REMOTE VOLUME CONTROLLER

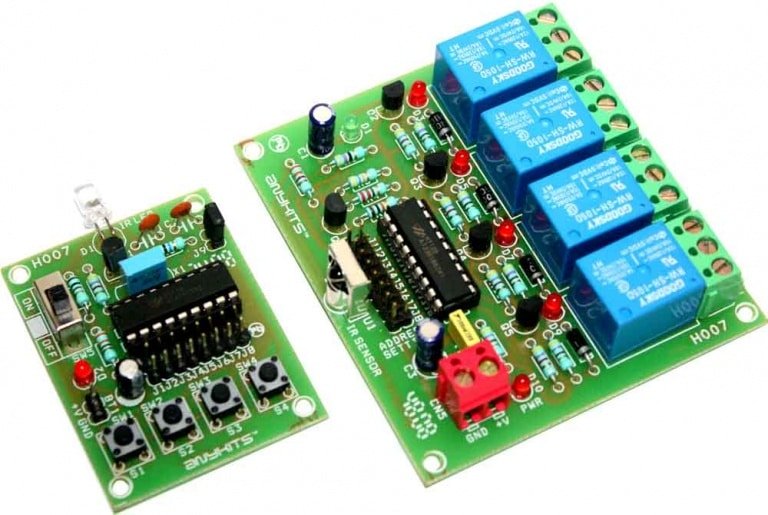

4 CHANNEL INFRARED REMOTE RELAYS

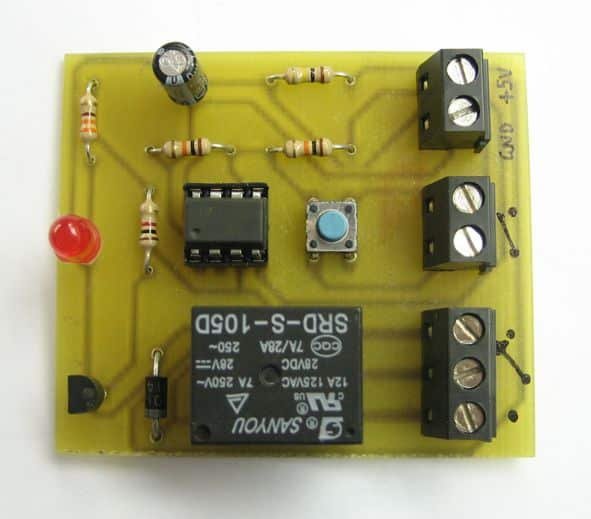

TOGGLE ON / OFF SWITCH

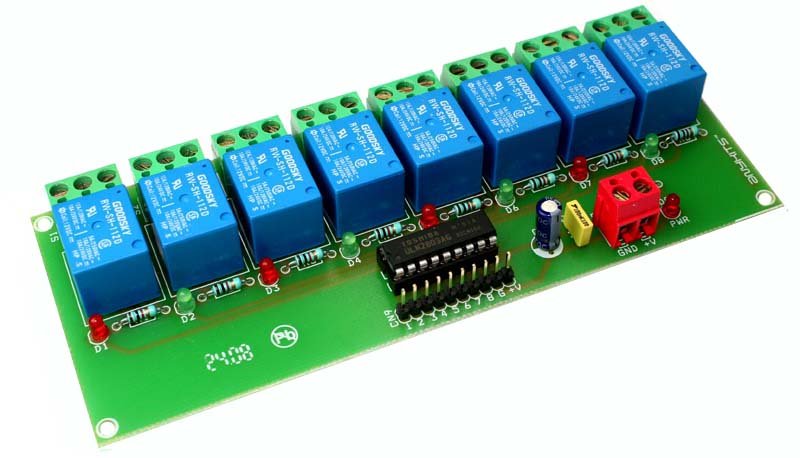

8 CHANNEL RELAY BOARD

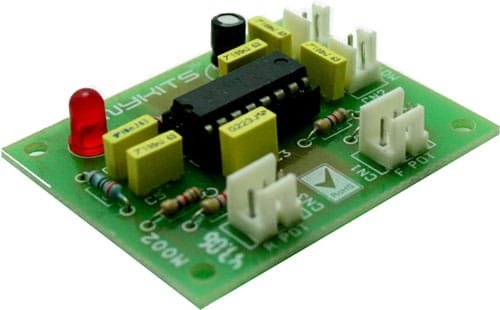

ELECTRONIC TOGGLE SWITCH

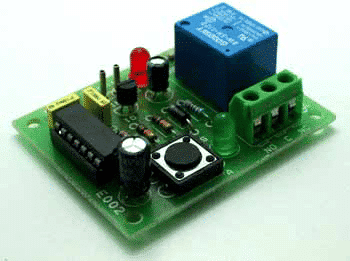

ONE CHANNEL RELAY DRIVER

DC MOTOR DIRECTION CONTROLLER WITH TACT SWITCHES

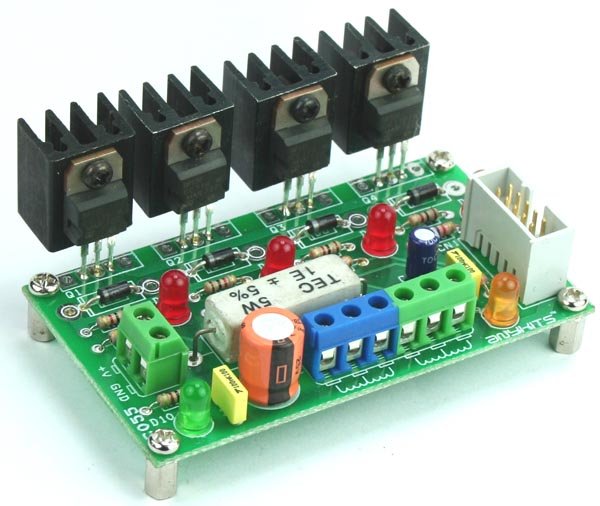

DC SERVO MOTOR DRIVER

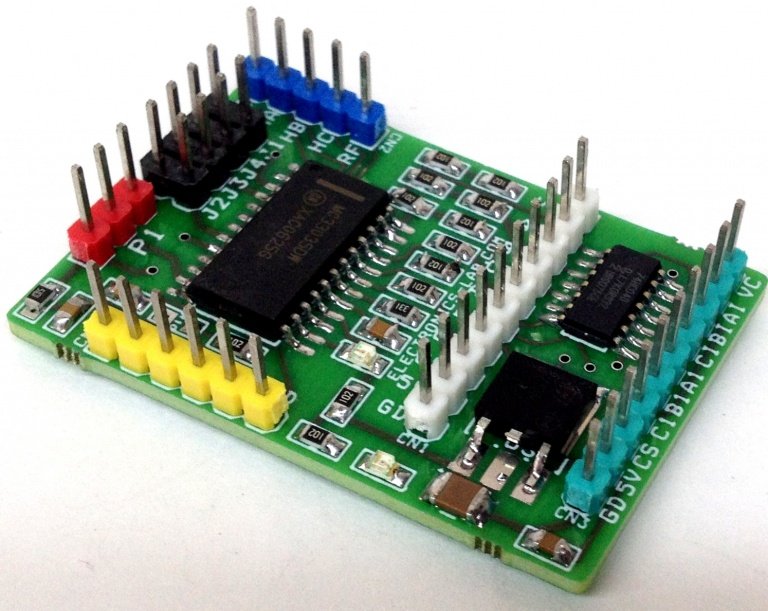

UNIPOLAR 4-PHASE STEPPER MOTOR CONTROLLER

RC SERVO DRIVER 0-5V

L293D DC MOTOR DRIVER MODULE

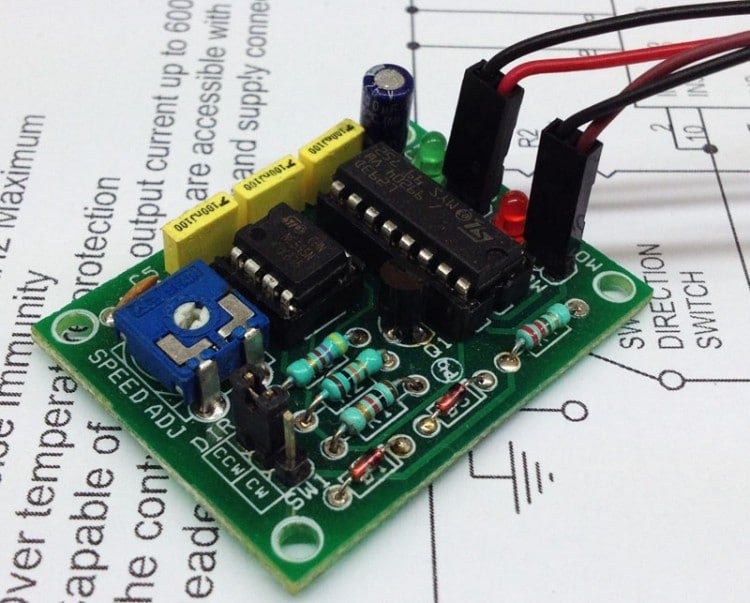

DC MOTOR SPEED AND DIRECTION CONTROLLER USING L293D

HALF BRIDGE DRIVER BASED ON IR2104

AC MOTOR SPEED CONTROLLER USING U2008B

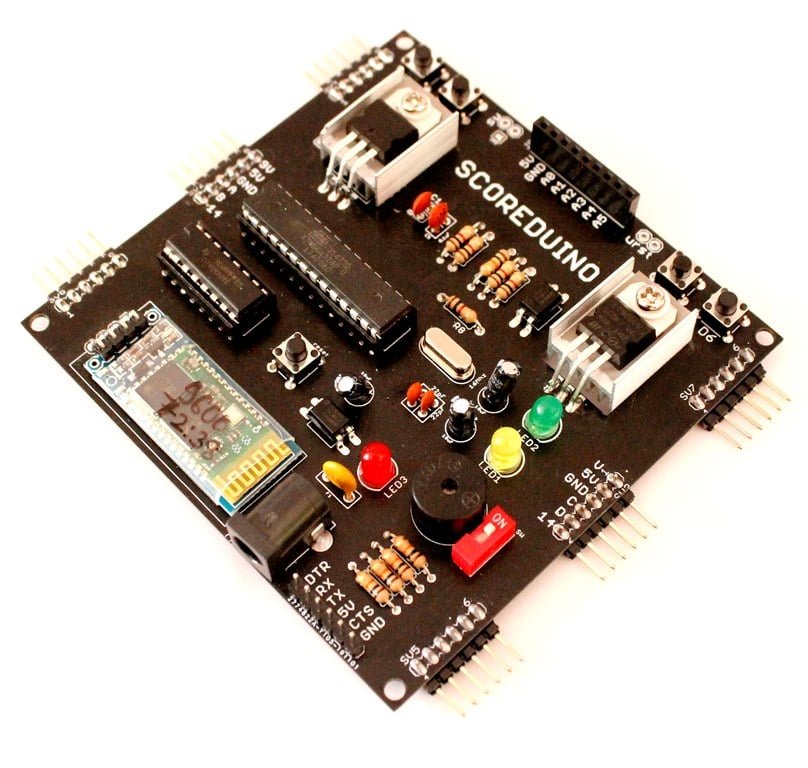

Scoreduino-B Arduino based controller for digital scoreboards

Single digit common anode up and down counters/drivers for seven segments displays

PULSE GENERATOR FOR STEPPER CONTROLLER USING AD654

Scoreduino-A Trigger Module For Up and Down Counter Drivers

Basic trigger module for up down counters

Single digit up and down counter using 74LS192 and RF remote control

Scoreduino

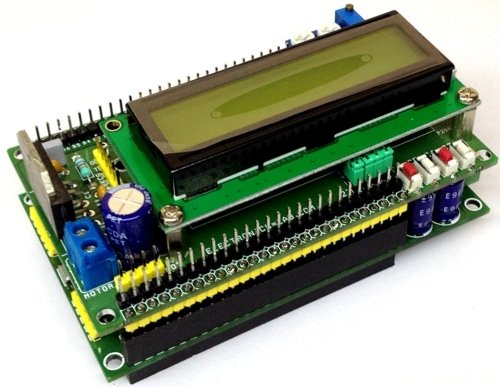

16X2 LCD SHIELD WITH LMD18201 MOTOR DRIVER

DC MOTOR & DIRECTION CONTROLLER WITH BRAKE USING MC33035

Make a seven segment display using 5mm LEDs

2X L298 DUAL DC MOTOR DRIVER BOARD FOR ROBOTS

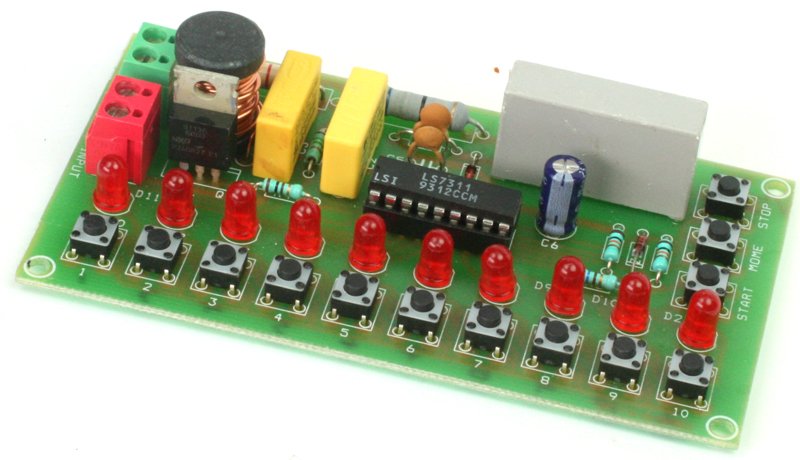

AC MOTOR SPEED CONTROLLER FOR MODERN APPLIANCES USING LS7311

2.5A 2 PHASE MICRO-STEPPING STEPPER MOTOR DRIVER

50V – 10A BIDIRECTIONAL DC MOTOR DRIVER USING A3941

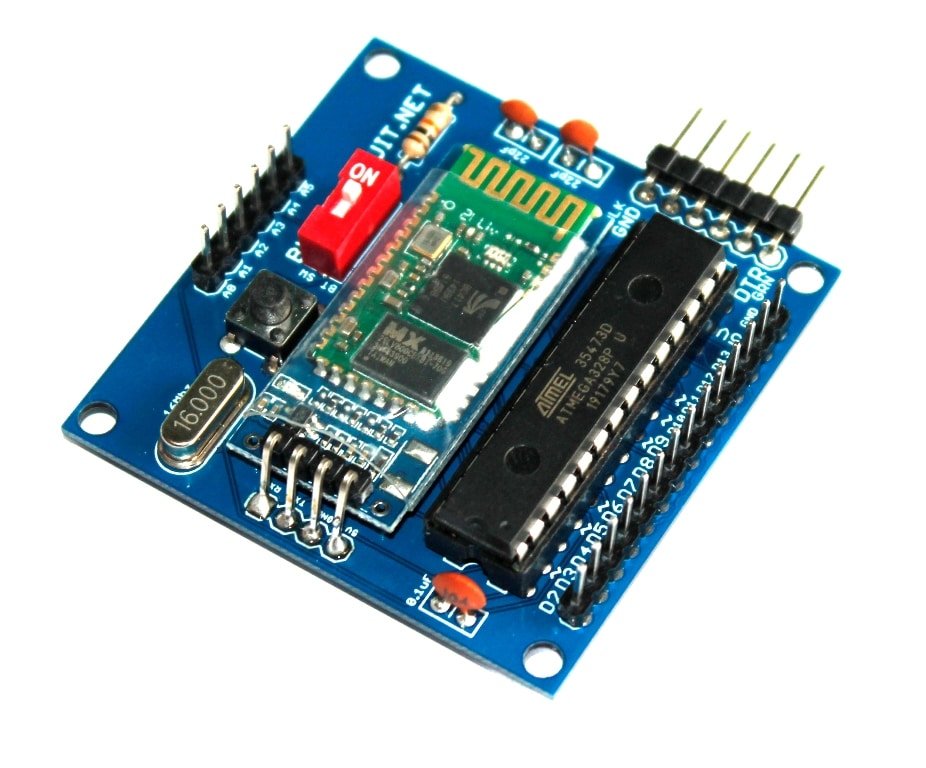

Popular Android Apps for 12CH Bluetooth Arduino module

3.5A UNIPOLAR STEPPER MOTOR DRIVER

MC33035 BRUSHLESS MOTOR DRIVER BREAKOUT BOARD

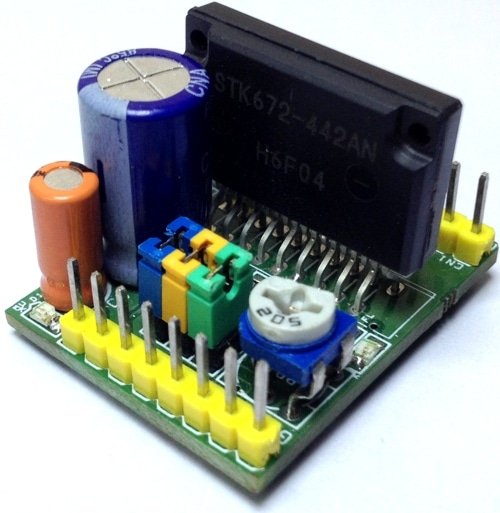

4A PWM CONTROLLED UNIPOLAR STEPPER MOTOR DRIVER USING STK672-740

15A 100V ISOLATED HALF-BRIDGE DRIVER

3V TO 5V BOOST DC-DC CONVERTER USING MAX711

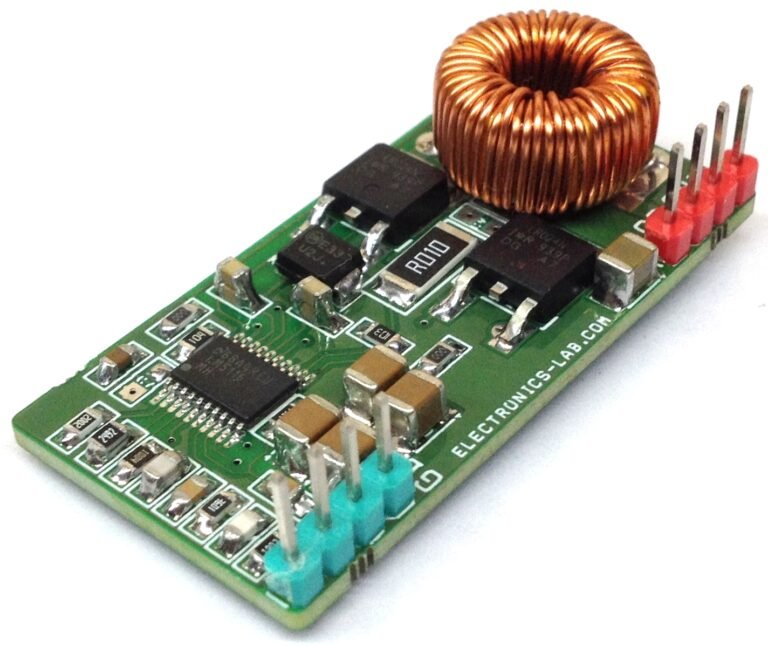

50V TO 5V @7A SYNCHRONOUS BUCK (STEP-DOWN) CONVERTER

SINGLE 18650 LIPO BATTERY TO 5V BOOST CONVERTER

USB (5V) TO DUAL OUTPUT +/-15V OR +/-12V STEP-UP DC-DC CONVERTER

200W LAMP FLASHER

555 STEPPER PULSE GENERATOR

10 factors that affect the transmission range of DIY FM Transmitters

DARK SENSITIVE SWITCH

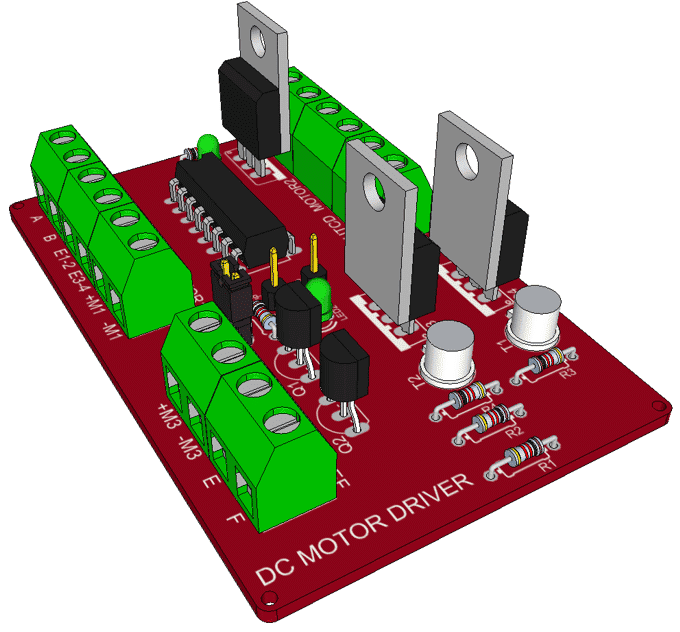

DC MOTOR DRIVER USING L293D

TRIAC BASED LAMP DIMMER

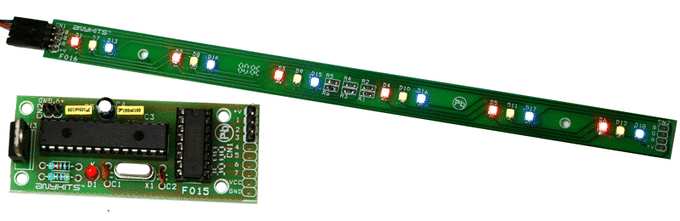

MICROCONTROLLER BASED RUNNING LIGHT CONTROLLER

RGB LED DISCO LIGHTS

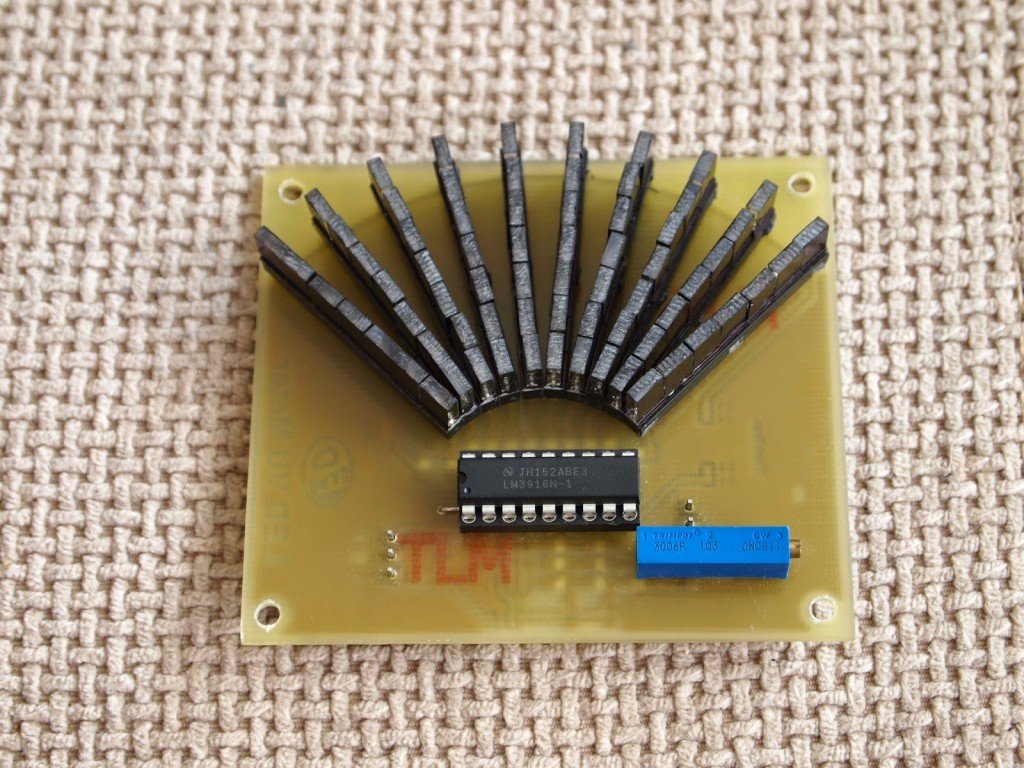

LED VU METER WITH LM3916

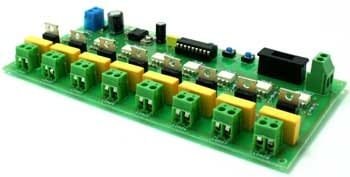

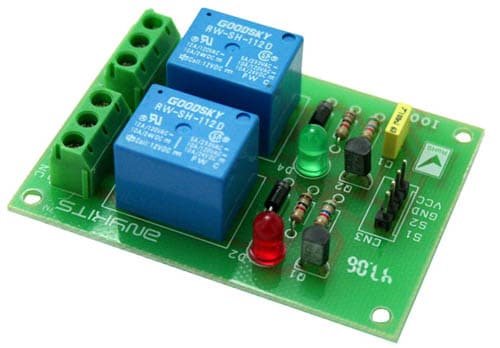

2 CHANNEL RELAY BOARD

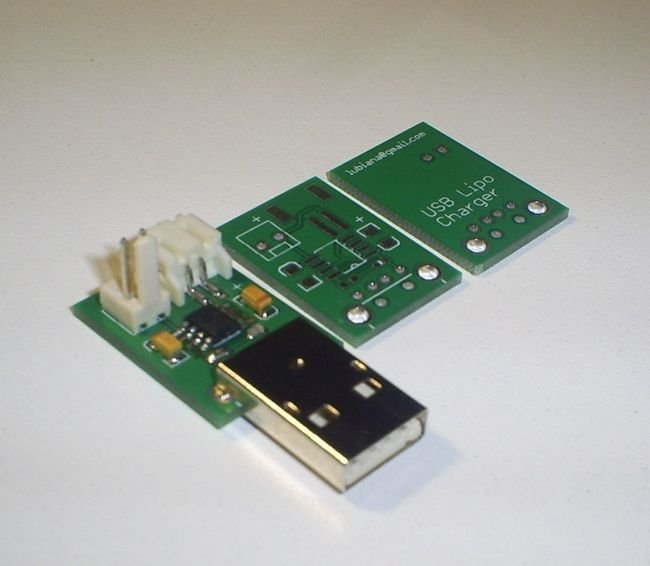

USB SINGLE CELL LIPOLY CHARGER

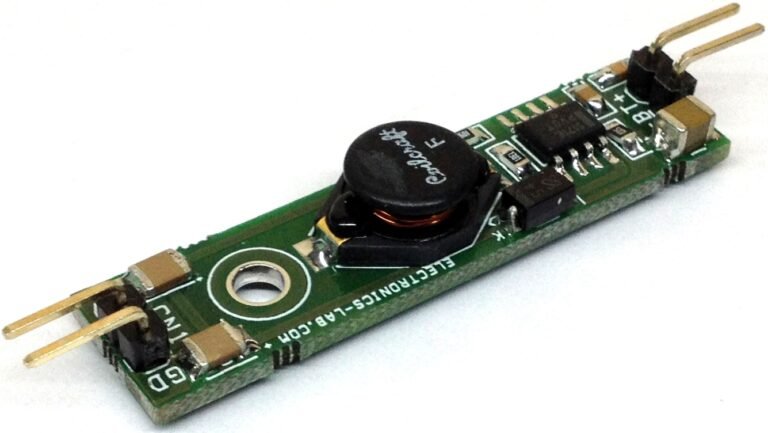

LASER DIODE DRIVER

SINGLE CHANNEL SMD RELAY DRIVER

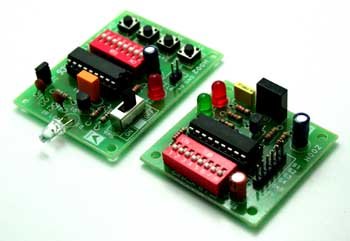

4 CHANNEL INFRARED REMOTE MODULE

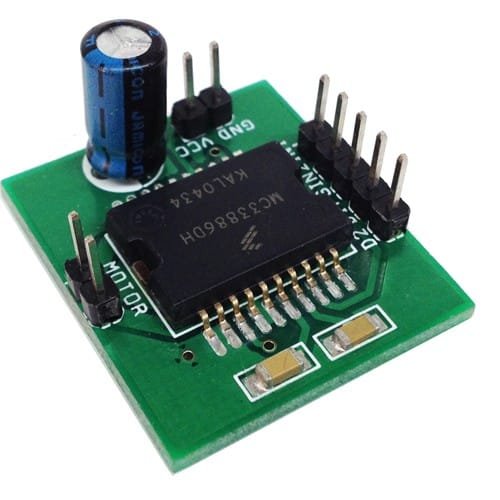

5 AMP H-BRIDGE DC MOTOR DRIVER USING MC33886

November 13, 2020